Plasma furnace PP-500/1000 is universal and can be used for the treatment and disposal of various waste include Municipal Solid Waste, Biomass, Scrap Tire, Plastic Waste and others.

It has a capacity to process 500/1000 kg per hour of waste. Plasma furnace can be equipped with plasma arc torches PPT-200AC of 200 kW each. Power used by the system 600-1200 kW.

Plasma facility can include one-two plasma furnaces PP-500/1000 with total performance up to 25-50 tons per day of waste.

Furnace PP-500/1000 is used to safely treatment of waste. The main element of plasma technology is a plasma arc torch.

A plasma torch uses gas or steam and powerful electrodes to create plasma with a temperature up to 3000-6000 degrees Celsius, which allows for full decomposition and disintegration of organic components.

After this processes all presenting toxic and hazardous components are completely removed from the resulting product.

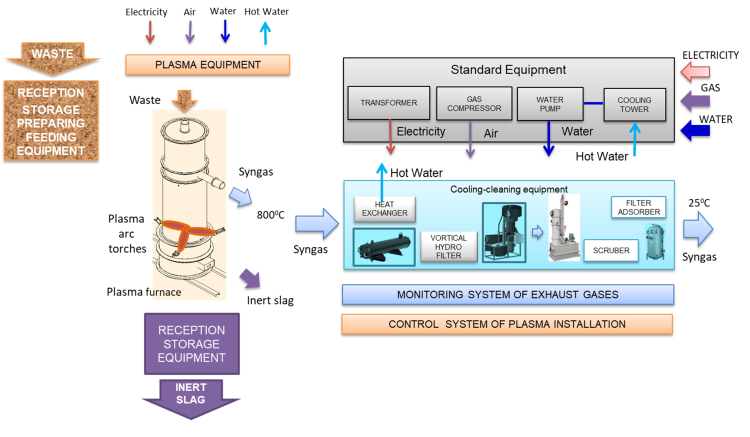

Basic set of Plasma Furnace PP-500/1000 has the following configuration:

• Plasma pyrolysis furnace PP-500/1000

• Plasma arc torches PPT-200AC (3-6 units)

• Waste-feeding system

• System for slag removal

• Pre-cleaning and cooling system of syngas

• Control system

Plasma arc torch non-transferred mode PPT-200AC of 200 kW

Quenching and pre-cleaning system of syngas

Quencher is necessary for a sharp drop in the temperature of the syngas from 600-1200°C to 200°C. Simultaneously, it allows to receive hot water, which can be used for various needs.

The vortical hydro-filter "Vortex" combines in itself functions of a wet cyclone and a filter. "Vortex" ensures high efficiency of gases purification from flying ashes, dust and aerosols.

After the vortical hydro-filter, syngas can be go to alkaline or acid scrubber, absorber and filters.

Optional equipment

Plasma furnace PP-500/1000 can be equipped with a multi-step system for purification of emissions and its hazardous components: after-burning chamber, dry cyclone, scrubber, absorber and filters.

As a result, the amount of residual hazardous components fully conforms to the international norms, and hence the plasma furnace is safe to use anywhere in the world.

In addition, PP-500/1000 can be equipped with a modern system for control and monitoring emissions of harmful substances into the atmosphere, which, together with a flexibling tuned plasma technology, will allow timely reacting and managing the protection of the external environment.

Synthetic gas, thermal energy and by-products are produced as a result of this plasma pyrolysis process could be reused. Electrical and heat energy can obtained from synthetic gas with the aid of gas generators could be used for various local needs and sales.

Plasma furnace PP-500 could be easily dismantled, transported and could be assembled at a new location.

Scheme of the plasma facility by one plasma furnace PP-500/1000

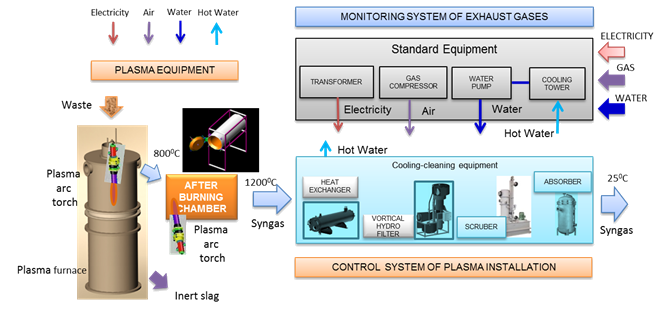

Plasma Furnace PP-50U

Plasma furnace PP-50U is universal and can be used for the treatment and disposal of various organic waste including also bio-medical waste. It productivity is up to 50 kg per hour using plasma torches up to 100kW.

Plasma Furnace PP-50U has control equipment; also can has exhaust gas cooling and pre-cleaning equipment, monitoring equipment of exhaust gas composition (optional).

For treatment of biomedical waste this plasma furnace is equipped with afterburning chamber and plasma arc torches of general power up to 150kW.

Basic set of Plasma Furnace PP-50U has the following configuration:

• Plasma pyrolysis furnace PP-50U

• Plasma arc torch PPT-100DC

• Afterburning chamber (optional)

• Plasma Arc Torch PPT-50DC (optional)

• Pre-cleaning and cooling system of syngas

• Control system

Plasma arc torch non-transferred mode PPT-100DC up to 100 kW

Scheme of the plasma facility by one plasma furnace PP-50U

The plasma furnace PP-50UM can also be supplied in container design for the solutions of tasks of mobile treatment of waste.

We offer ecologically clean plasma technology