Plasma Furnace for treatment of Hazardous waste

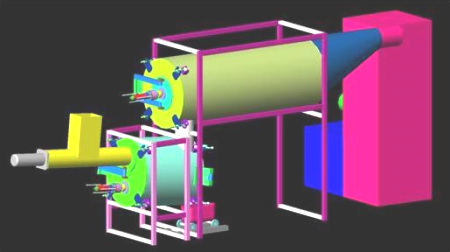

Plasma Furnace PP-50M for the treatment of Biomedical Waste

Plasma technology provides an effective and safe alternative for the destroying of Biomedical Waste. The plasma process destroys toxic components (germs, viruses, bacteria, etc.) and incinerates organic constituents of waste and compact’s mineral residual.

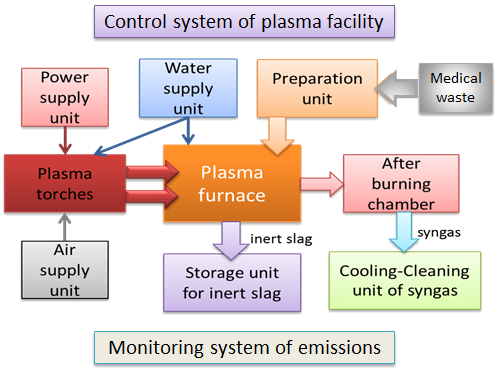

Plasma furnace PP-50M for treatment of Biomedical Waste has a performance up to process 50 kg/hour. Plasma torches power used the furnace with an afterburning chamber is up to 150 kW. The PP-50M has the following configuration:

• Plasma combustion chamber with one plasma torch;

• Afterburning chamber with one plasma torch, to prevent the formation of dioxins and furans;

• Unloading device for removal the slag from the furnace;

• Electric supply, water supply and gas supply control panel.

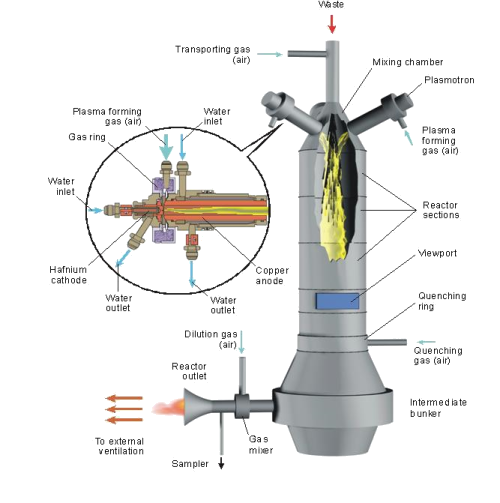

Plasma arc torch PPT-100 with a power of 60-100kW for plasma furnace PP-50M

How the plasma furnace for hazardous waste treatment works

How the plasma furnace for hazardous waste treatment works

The process of waste incineration is two-stages. First the waste is incinerated inside the furnace using plasma pyrolysis and then the leftover pyrogas is incinerated in an afterburning chamber, which is especially designed to include all the ecological parameters for effective incineration.

It is impossible to achieve the same parameters for incineration in an ordinary furnace only. Air plasma torches not only effectively pyrolyze waste, but also vitrify its ash slag at a temperature of 1500-1800 Degrees of Celsius.

The positioning of the plasma torches is designed in such a way so that plasma stream comes into direct contact only with the molten mass; refractory lining of the inner walls of the furnace remains untouched.

Plasma Reactor PR-50 for the treatment of Chemical Waste

Plasma Pyrolysis Reactor PR-50 is used as a basis for the system that treats gaseous, liquid and disperse medical, toxic and chemical waste.

Power used by the system is up to 100кW.

By products (such as synthesis gas and powder) that are received as a result of the process can be used in other applications.

Electric energy generated through the process can be used for various purposes. 33 % of this energy is enough to work the reactor.

To ensure a safe operation of a reactor we build the strong, multilayered, tight case made of stainless steel and a water shirt to prevent any emissions from reaching the atmosphere.

The plasma pyrolysis reactor has three plasma torches which create a special vortex to ensure quality pyrolysis of waste. The basic scheme of the plasma pyrolysis reactor is shown in figure.

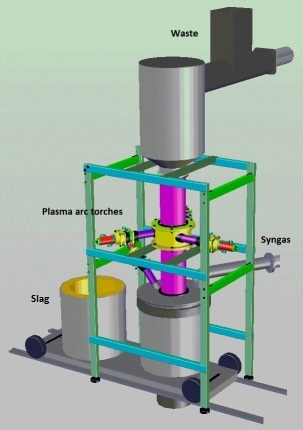

Plasma Reactor PR-100 for the treatment of Chemical Waste

Pyrolysis Reactor PR-100 of new generation uses modern plasma arc torches and makes it possible to build systems with higher productivity. Productivity of reactor is 100 kg/hour. Power used by the reactor is 150кW.

Plasma arc of disposal of Asbestos and Asbestos-containing Waste

Asbestos is known for its carcinogenic effect and poses a serious threat to the human body. However, its use for centuries led to a large quantity of this product contained mainly in a variety of building materials.

HTT Company is offered an environmentally safe recycling method of asbestos and asbestos-containing waste in a plasma reactor. When exposed to high temperatures in a plasma reactor is destroyed a fiber needle structure of asbestos. It turns into a solid, fully degassed, homogeneous slag, which is an inert glassy substance, consisting of a mixture of metal oxides.

HTT Company has received the vitrified slag in the test plasma reactor with a capacity of 20 kg per hour from asbestos-containing waste. The power of plasma generator is 50 kW. The performance of industrial plasma reactors can range from tens to hundreds of kilograms per hour. As plasma generators we use our plasma arc torches with power from 50 to 500 kW.

Types of asbestos, which can successfully be processed in a plasma reactor:

- 3MgO • 2SiO2 • 2H2O;

- (Na2Fe32 + Fe23 +) Si8O22 (OH)2;

- Mg6 [Si4O10] (OH)8; Ca2Mg5Si8O22 (OH)2.

The main advantages of the plasma method:

- High specific performance by a small size equipment;

- The ability creating of necessary atmosphere of the gas inside a plasma reactor and a treatment of various types

of asbestos-containing waste without pre-sorting;

- The significant reduction of volume of asbestos-containing waste and exhaust gas;

- The getting of final products in the form of fused slag compound, which has a high chemical resistance against environmental influences.

Vitrified inert slag

Plasma Furnace PP-200Asb for the disposal of Asbestos and Asbestos-containing Waste

Plasma Furnace is used for the treatment of asbestos and asbestos-containing waste. It has a power level up to 500 kW and a performance up to 200 kg/hour. The Plasma Furnaces PP-200Asb are shown in the following figures.

Plasma arc disposal of low-level Radioactive Waste

During operation of nuclear power plants and facilities of other industries, in the process of liquidation of consequences of accidents at these facilities and conducting scientific research produces large amounts of solid and liquid low-level Radioactive Waste (RW).

The use of low-temperature plasma technology for treatment of RW to get highly stable forms of processed products (with high chemical resistance to aggressive environmental influences) is promising.

The low-temperature plasma technology allows treating the solid and liquid radioactive waste of low-level of activity, such as fabric, paper, plastic, wood, process fluids, clothing, shoes, wires, etc.

The main advantages of plasma processing method for low-level RW:

• a greater reduction in the volume of RW and flue gases;

• getting the end-products in the form of remelted ash or slag compound with high chemical resistance to aggressive environmental influences.

The technological process of treatment of RW in a plasma reactor includes the following stages:

• Gasification of RW (incomplete evaporation and output of volatile components);

• Pyrolysis of organic part of RW with subsequent process of purification of pyro gas and its combustion in the chamber of the homogeneous combustion;

• Burning out the coke residue;

• Melting of the ash and incombustible impurities for obtaining chemically and mechanically resistant slag with a high content of radionuclides.

As a result of processing the volume of waste is reduced by 10-15 times, and the radionuclides are concentrated. The radionuclides are safely immobilized in the resulting product and cannot penetrate into the environment.

After the treatment of the RW is finalized, the inert slag is then disposed of in the normal way – burial or long term storage.

Vitrified inert slag

Plasma Furnace PP-100RW for the disposal low-level Radioactive Waste

Plasma Furnace PP-100RW is used for the treatment toxic waste and low-level radioactive contaminated wast. It has a capacity to process 100kg of waste per hour. Power used by the Plasma Furnace with an after burning chamber is 150 кW.

We offer ecologically clean plasma technology